Gas and Chemical Plant: Proactive Safety with AI

24x7

Monitoring

10x

Safety Observations

100%

Closure

Industry Problem

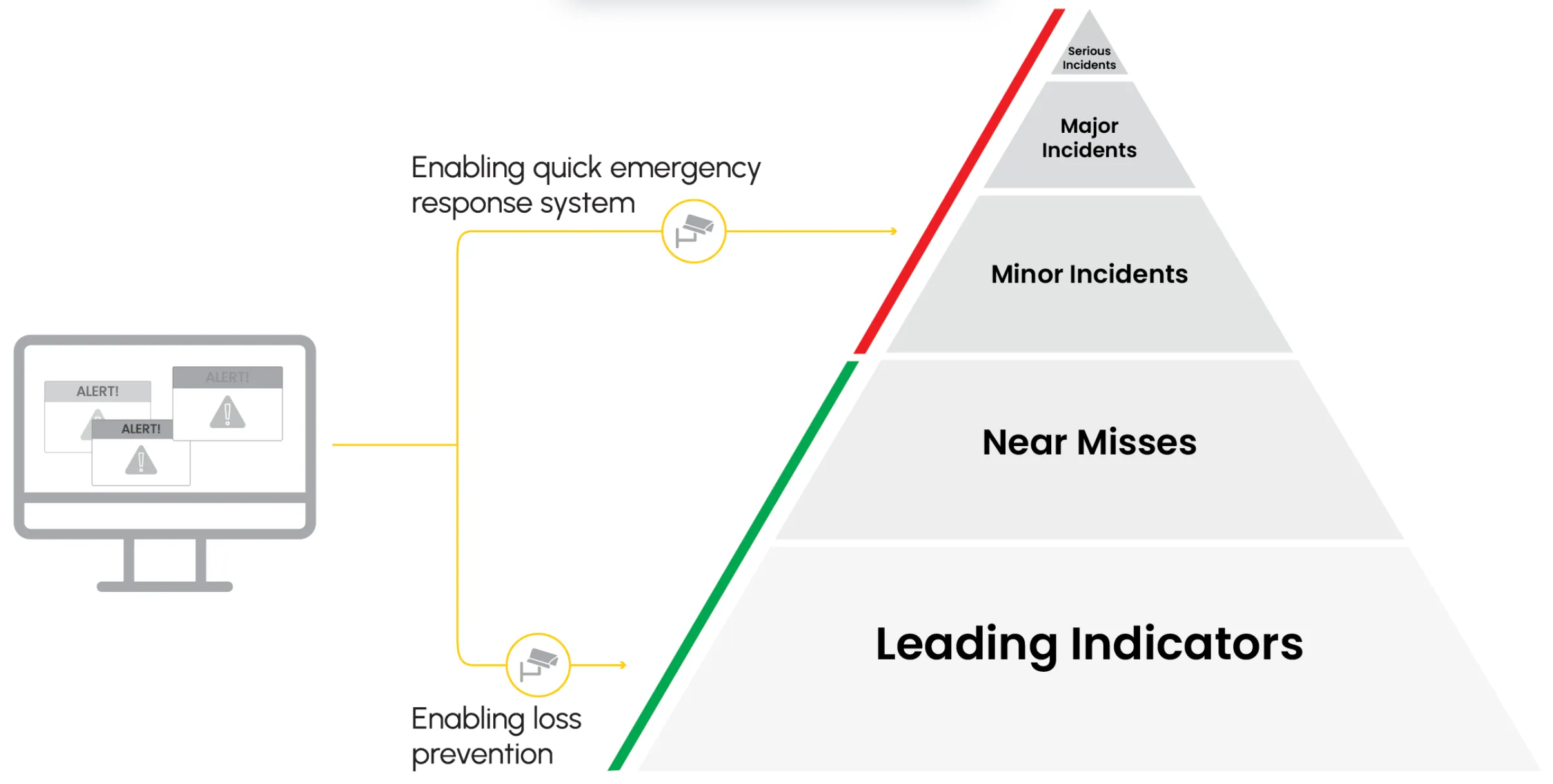

Workplace safety is a serious concern for organizations because only serious incidents or fatalities are being reported to the management. This leads to missing out opportunity to collect data for unsafe acts & conditions, near-misses, which can highlight leading indicators for serious incidents. In 2022 Occupational Safety and Health Administration (OSHA) reported almost 3.7 fatalities per 100,000 full-time equivalent workers, whereas statistics for leading indicators are missing.

The Challenge

In the bustling heart of Mumbai's industrial hub, a leading gas and chemical company manufacturer has deployed the best mechanisms of health, safety, and operational efficiency. Over the period multiple behavior and unsafe condition reporting tools has been used however company is not able to reach the level they want to, as the deployed mechanisms were unable to completely supplement the requirements.

The Analysis

Company is one the biggest advocate in adopting technology which could seamlessly integrate with their operations to enhance safety, security, traffic management and operational efficiency. Awiros’ team of experts worked closely with the company’s HSE and operations team to brainstorm the reasons and gaps lea w.r.t leading unsafe acts, unsafe conditions and nearmisses & their reporting. Session started with listing various unsafe acts and conditions from existing reporting tool and identifying highest occurring issues such as:

1. Non-compliance of Personal Protection Equipment(PPE) use in PPE zones

2. Non-compliance of walkway

3. Non-compliance of traffic rules, etc.

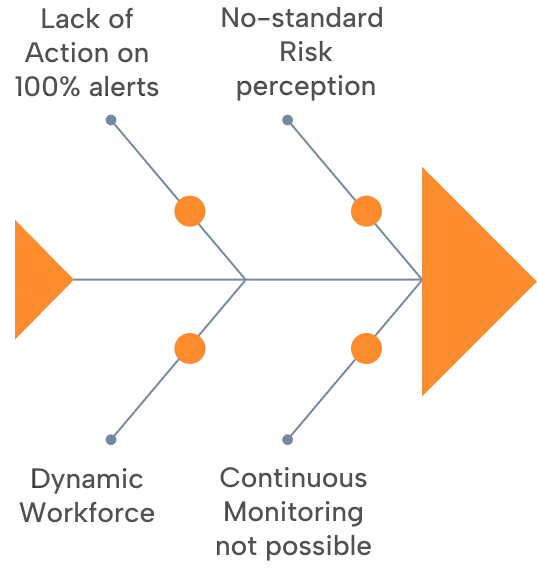

Brainstorming session also helped in identifying various cause for less or non reporting of unsafe acts/conditions/near miss:

1. Non-compliance of Personal Protection Equipment(PPE) use in PPE zones

2. Non-compliance of walkway

3. Non-compliance of traffic rules, etc.

Brainstorming session also helped in identifying various cause for less or non reporting of unsafe acts/conditions/near miss:

This concludes that most leading indicators has to be corrected through behavioral based improvements which in-turn can be done by removing human’s intervention in deciding, capturing & alerting higher management on any and all conditions or acts leading to major incident.

The Solution

After identifying the issues, way-forward was clear: deploy solution which uses combined power of Artificial Intelligence and advanced Video Analytics, to monitor and improve safety, security, traffic management and operational compliance at the plant. The initial phase involved installing high-definition cameras at key locations around the gas filling plant, including the main gate, walkways, weighbridge, liquified gas filling station, and the plant perimeter where maximum number of hazards are reported. These cameras began capturing video footage essential for training the computer vision models. The Awiros team collected field videos, developed applications to process and analyze the data, and created models to detect anomalies, ensure PPE compliance, and monitor vehicle and human movements. After following rigorous testing to ensure accuracy and reliability solution was deployed on field for 1 month.

This helped in following:

1. 10X increase no. of observations as video is being captured & analyzed 24X7, thus removing dependency of presence of observer to raise alert

2. Removing human’s risk assessment factor, as alerts for unsafe acts and unsafe conditions are generated through defined rules.

3. 100% action on alerts through alert escalation mechanism.

This helped in following:

1. 10X increase no. of observations as video is being captured & analyzed 24X7, thus removing dependency of presence of observer to raise alert

2. Removing human’s risk assessment factor, as alerts for unsafe acts and unsafe conditions are generated through defined rules.

3. 100% action on alerts through alert escalation mechanism.

The implemented solution directly increases the leading indicators, which in-turns allows management to take proactive data based actions to decreases serious accidents and fatalities.

The Impact

Operational Compliance Monitoring

Automated inspections and timely alerts enhanced operational efficiency by preventing disruptions and ensuring smooth operations

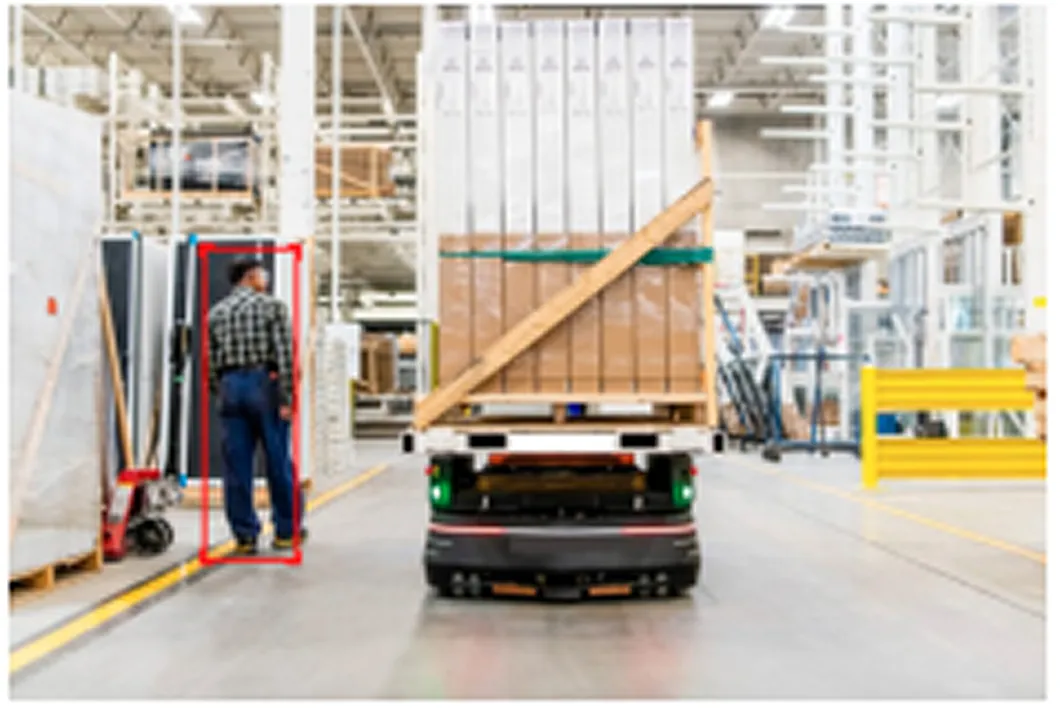

Man-Machine Segregation

Removing & reducing human’s interaction with machine by real-time audio alerting & reporting whenever unrequired man-machine interaction happens.

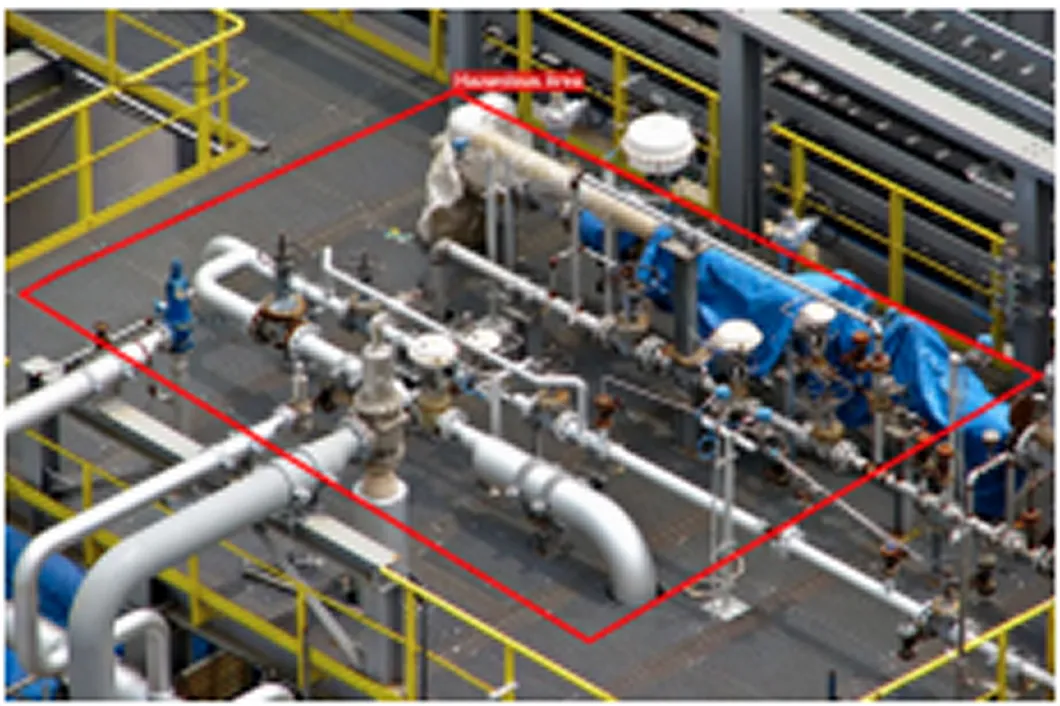

Hazardous Area Access Management

Reduced unauthorized access, leading to improved human safety & theft of critical material and equipment

PPE Matrix compliance

Real-time monitoring and alerting significantly improved PPE compliance, reducing the risk of accidents.

Road Safety

Improved gate opening compliance, traffic management and traffic safety compliance with 24X7 monitoring & actions on noncompliances

Smarter insights. Better outcomes. Start with Awiros.